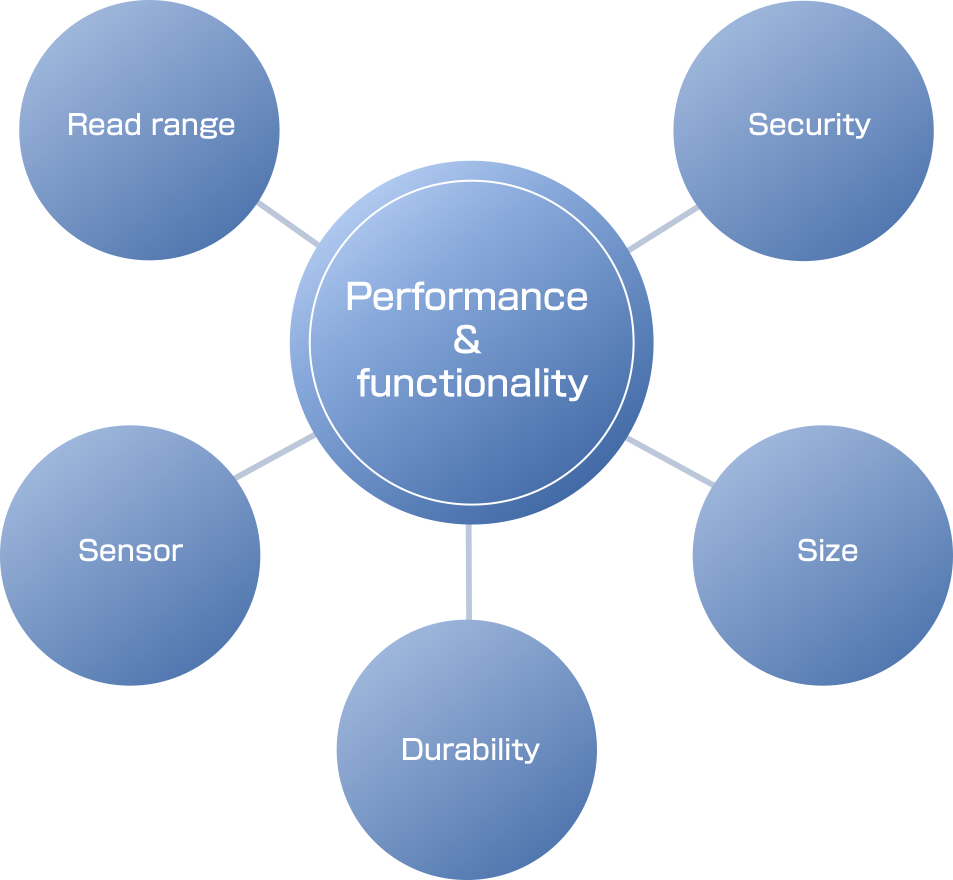

We have been delivering integrated RFID solutions for diverse industries, available to propose tags with the optimum performance upon customers’ requirements.

Solution

Analysis and product planning

Read range

RFID products are sensitive to the surrounding environment. We work alongside RFID professionals who will listen to your operating environment and design an optimum antenna

Security

We provide support from the selection of chip type to the setting of encoding content, taking into account the operation method and system content.

Sensor

These tags are equipped with sensors (temperature, humidity, illumination, shock detection, etc.) to streamline the management of all objects.

Size

Through integrated in-house management, complex design aspects, such as minimum size and even challenging shapes of tags are possible.

Durability

RFID products are susceptible to environmental conditions. We develop high performance tags with features and options specific to certain environments from selecting antenna and case base material types.

Design and prototype

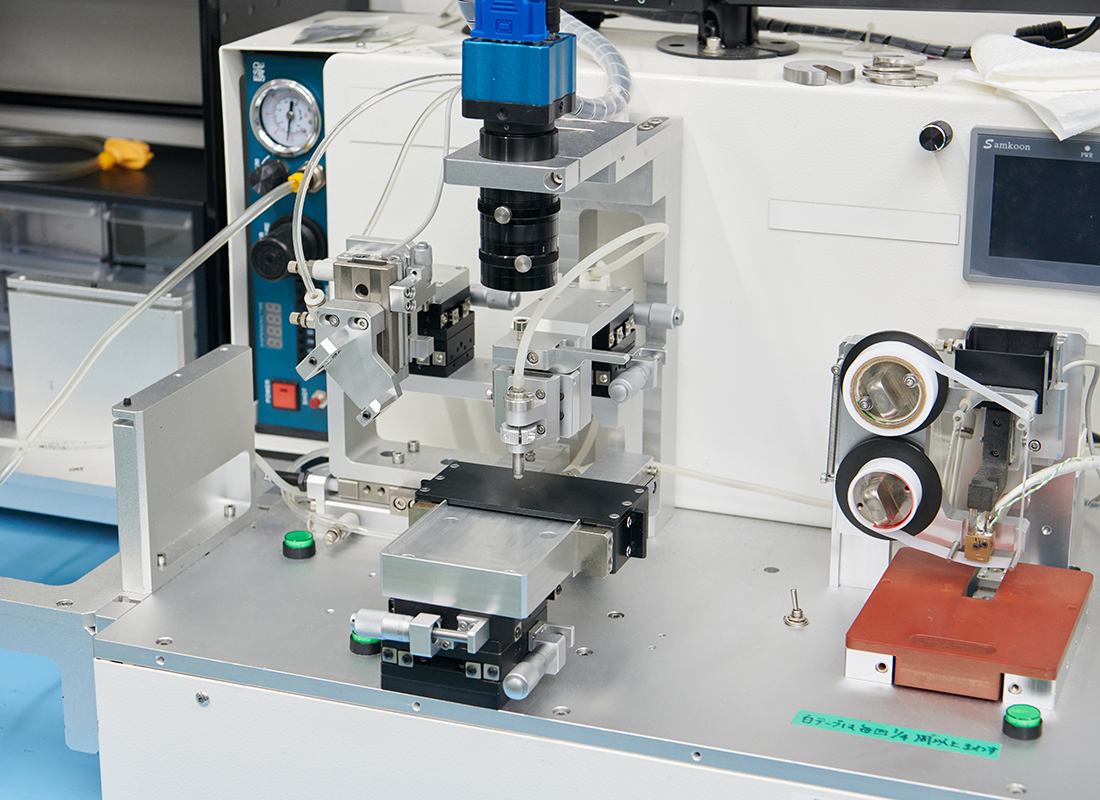

RFID IC Circuit manufacturing

Several manufacturing methods are available to be selected from to suit the customers’ requirements.

Antenna manufacturing

Copper wire antenna

Copper has a lower resistance than aluminum, therefore the antenna has a lower resistance, a higher Q factor, and better performance. And also copper wire antenna can be made small.

Aluminum etched antenna

Mass production and cost-effective tags and cards are possible.

Flip chip bonding

The chip is flipped on the substrate during mounting.

It is placed directly on the antenna, and can be made into a product with “space saving” and “high conductivity” feature, compared to wire bonding and other methods.

Spot bonding

This method uses wires to bond the chip and antenna. By welding the wire, the bonding area between the chip and the bump is expanded to realize high durability and conductivity.

Tag housing

We are available to make cases by injection-molding process.

We have know-how to propose base materials with properties such as durability and chemical resistance to suit specific environment.

Casing

Ultrasonic welding

A processing technique where ultrasonic vibration and pressure are applied to thermoplastic resins (ABS/PC/PP, etc.) to weld them together.

Heat welding

A processing that melts and welds materials by heating and applying pressure up to their melting point.

Available in diverse combination of materials using special adhesive.

Resin sealing

Potting and encapsulating resins(Thermosetting/UV hardening/natural hardening) on base materials offers high level protection.

Small lot orders are available.

Design

Silkscreen printing

A printing method pressing ink through a plate to create a printed design.

In addition to colour printing on plastic cases and other materials, special colour printing is also available.

Double injection

Unlike usual injection moulding, which can only produce a single colour, this is a technology combines different materials.

By using different coloured materials, it is possible to create designs on the case.

Laser engraving

Laser engraving in three different wavelengths is available.

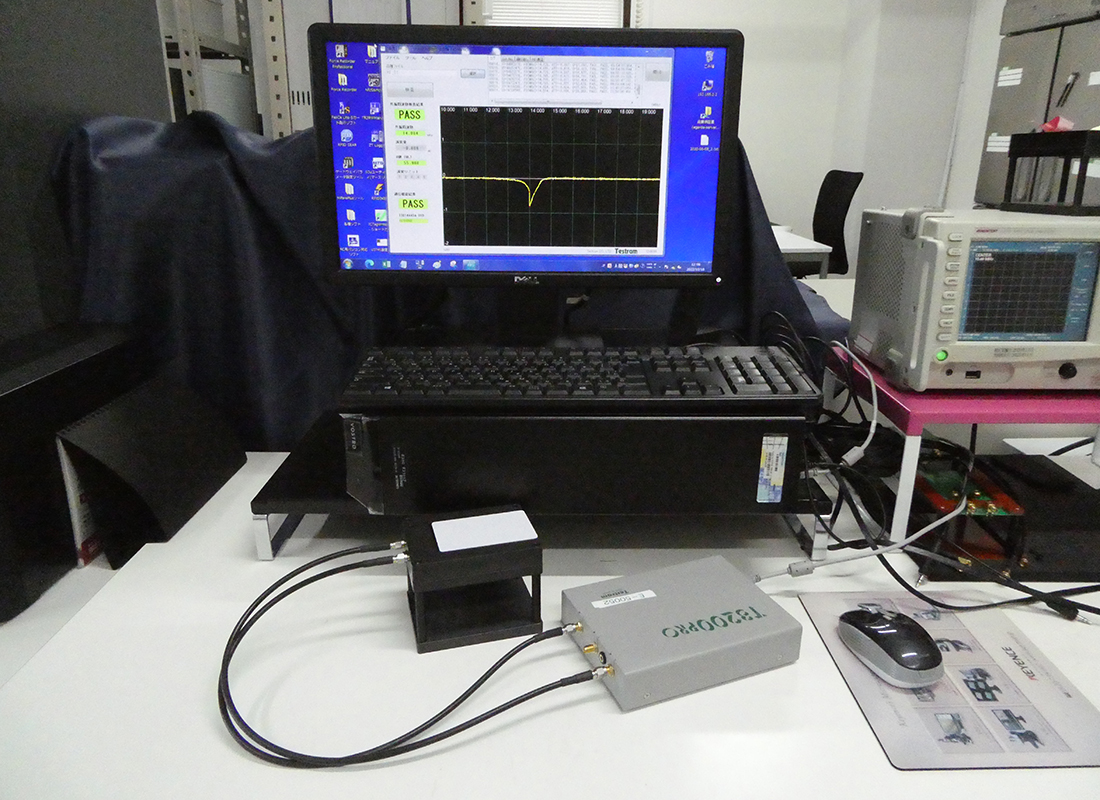

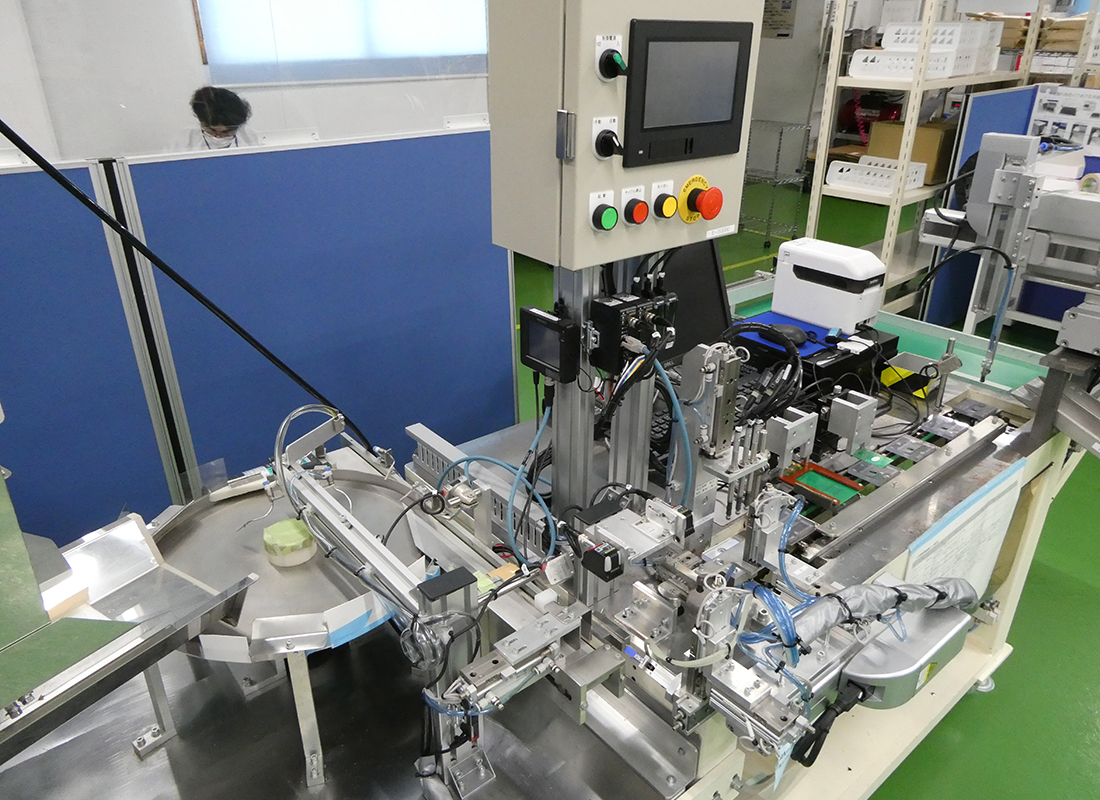

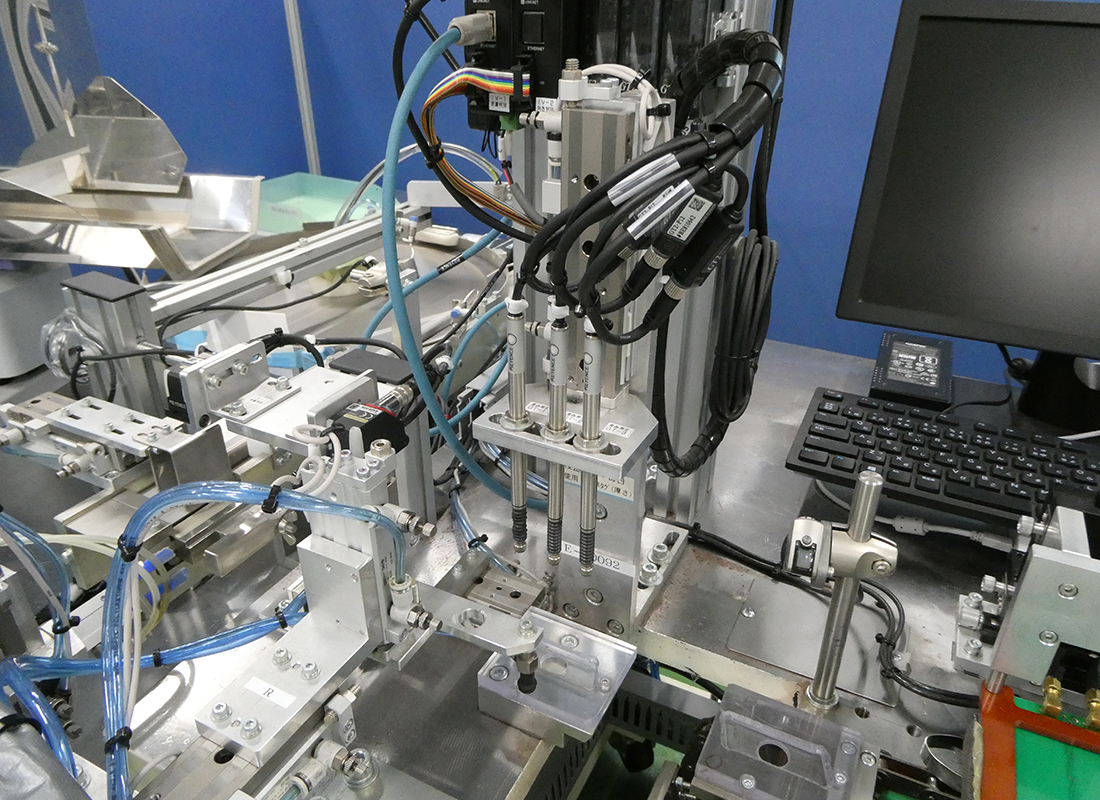

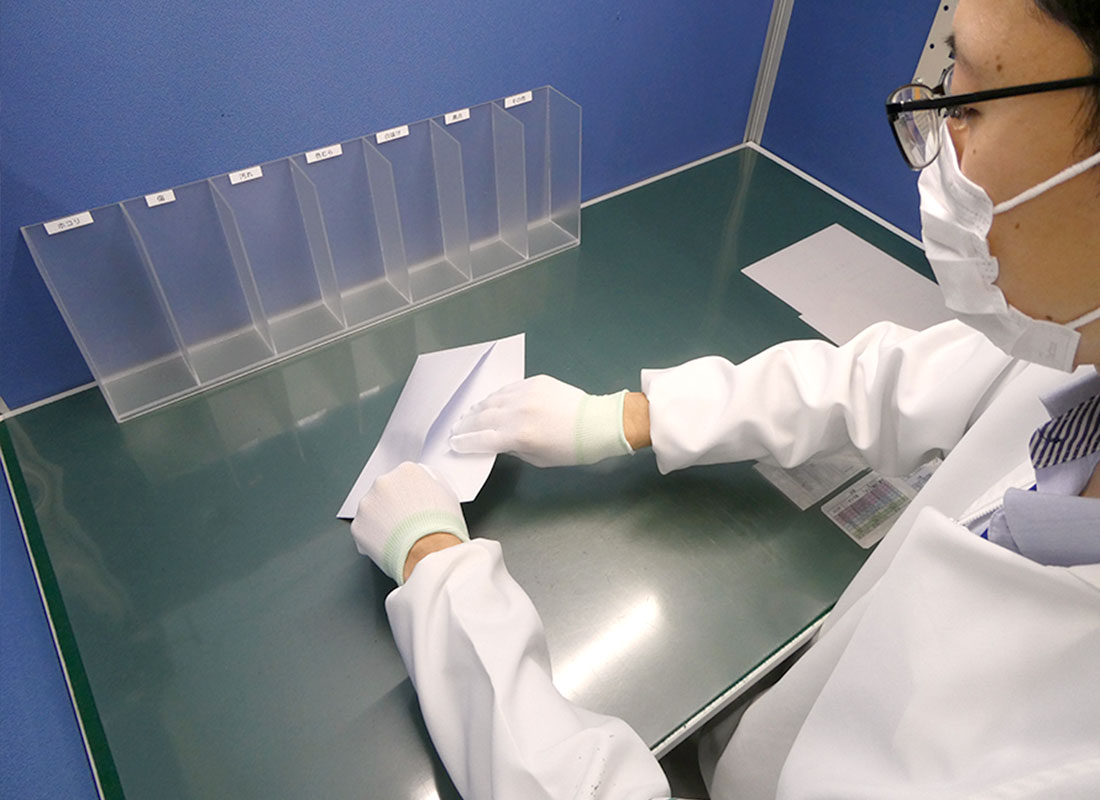

Automatic inspection machines with encoding function.

There are several machines in Tokyo factory capable of processing more than one million IC tags per month, simultaneously performing encoding, laser engraving, FQ & read inspection, and thickness inspection. With the in-house software development team, we respond quickly to newly launched ICs.

Valure-added

Packing and sealing

Bagging to prevent damage

On-metal tag

Process for performance in contact with metals.