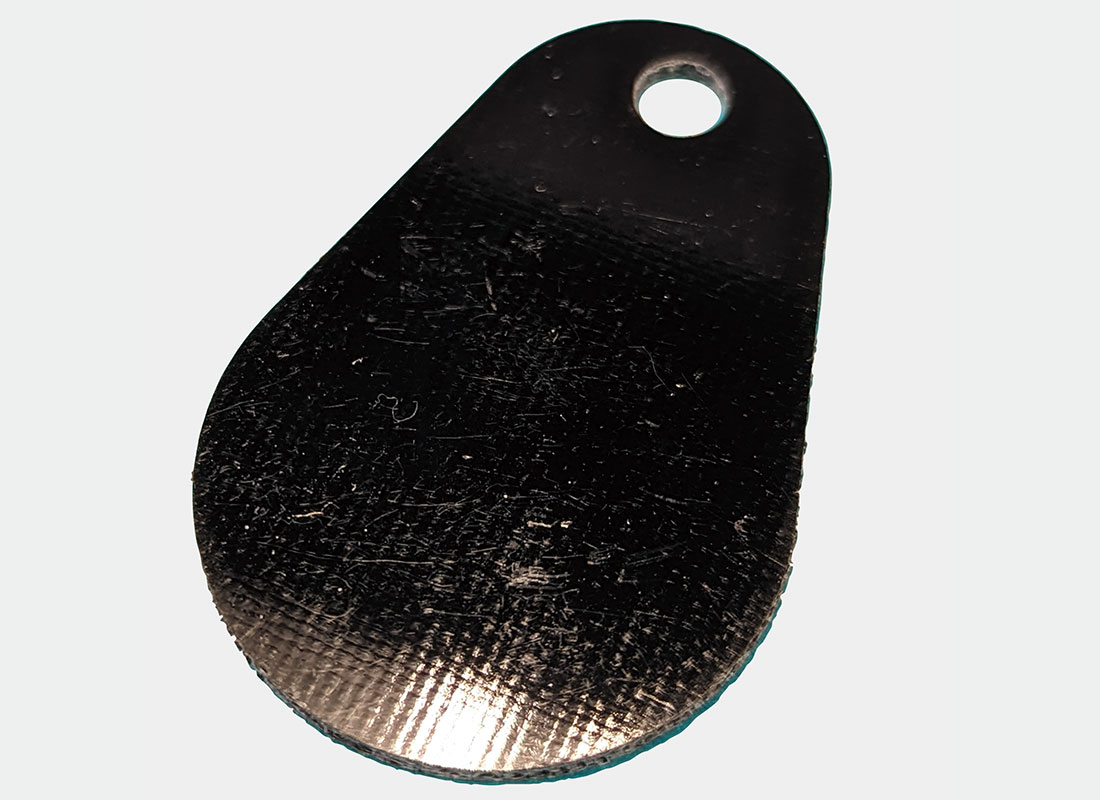

We use FR4 as one of the sheet materials when making tags. It is widely popular among this field. FR4 sheets have high dielectric strength. Also, given the fact that it is heat-resistant, it is ideal to be used in substrate, mounting and casing, and products for long-term use in harsh environments.

Circuit for RFID IC

Antenna design

In addition to standard products, antennas can be designed according to customer requirements (antenna size, substrate material, etc.).

A wide range of frequency bands (HF/UHF/LF) are available.

Antenna manufacturing

There are two main types: Aluminum etched antenna and copper wire coil antenna. There is an option for antenna substrate which can be made of paper.

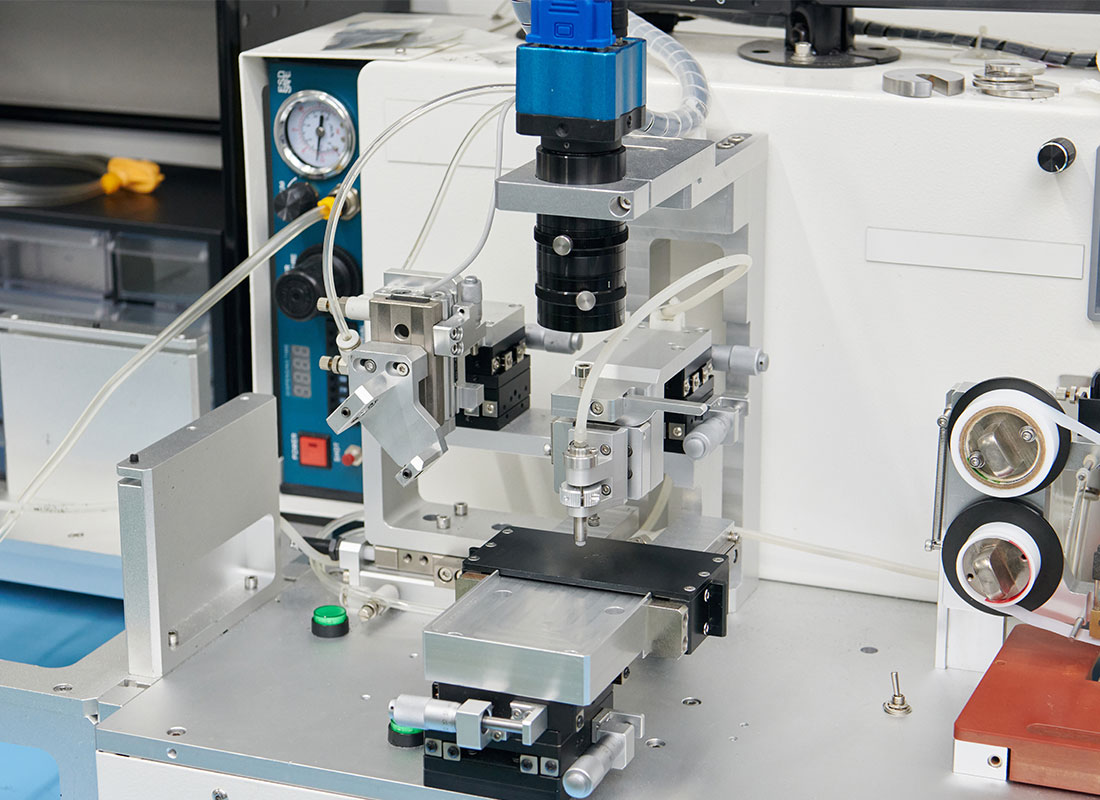

Bonding

We offer several bonding methods to suit the operating environment, including wire bonding, SMT mounting and ACP mounting.

We can also handle small-lot projects such as prototypes.

Resin sealing technology

It is resin sealing process to protect the chip itself and the mounting area.

The type of resin used in the process can be selected.

Small lots are available.

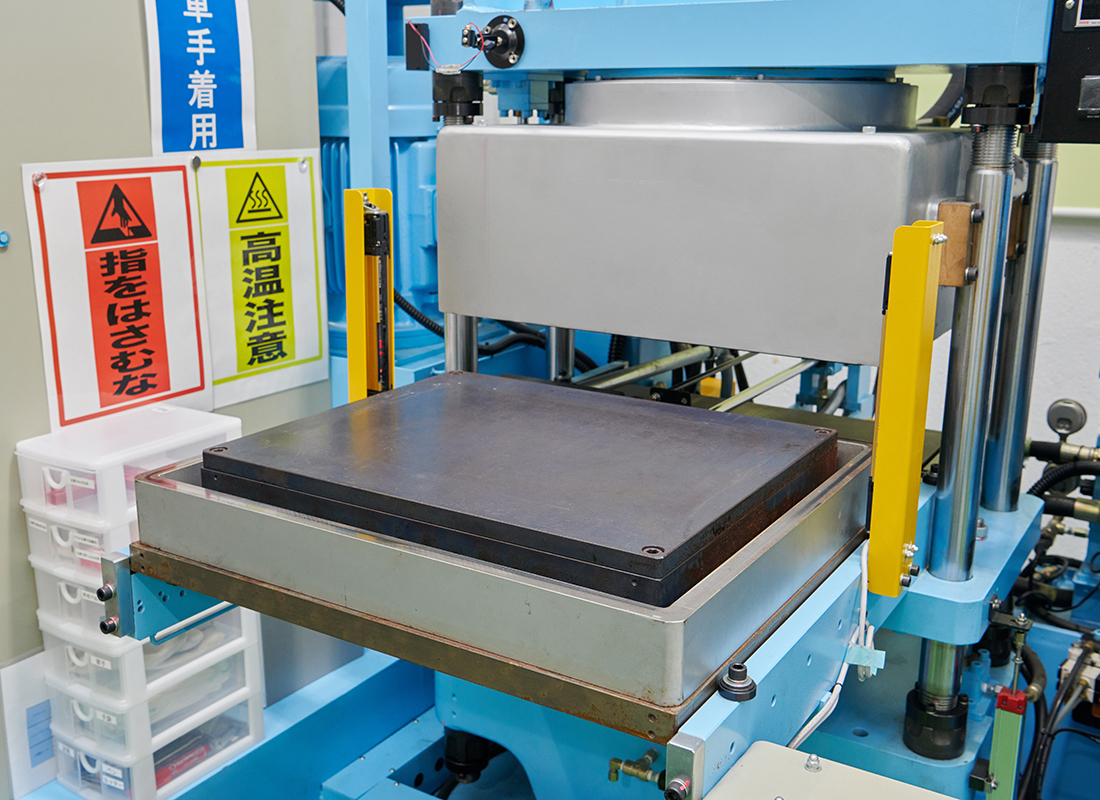

Laminating technology

Lamination

This is a device used to press the same materials, as well as different materials using a special bonding adhesive.

Laminated with durable materials, the tags are highly heat and shock resistant.

Surface finishing

There are two types of surface treatment for products made of FR4 material.

Laser engraving

Laser engraving can be carried out on the face of the tag.